When planning a project, whether it’s in construction, manufacturing, or even custom design, choosing the right material is crucial. One material that is gaining popularity for a variety of applications is aluminum extrusions.

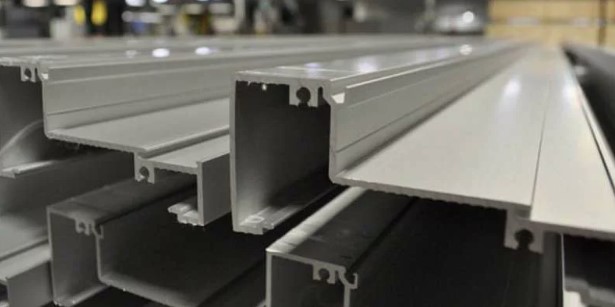

Aluminum extrusion involves pushing aluminum through a die to create a specific shape or profile. This versatile process produces products that are both lightweight and durable. In this article, we will explore five key reasons why you should consider aluminum extrusions for your next project.

1. Lightweight Yet Durable

Aluminum extrusions are known for being lightweight, which makes them easy to handle and transport. This is especially beneficial for projects where weight is a factor, such as in the construction of frames for windows or doors, or in the automotive industry.

Despite their lightness, aluminum extrusions are surprisingly strong and durable. Aluminum naturally resists corrosion, meaning that your project will remain in good condition for a long time, even in harsh environments.

2. Versatility in Design

One of the main advantages of aluminum extrusions is their versatility. Aluminum can be extruded into a wide range of shapes and sizes to meet the specific needs of your project. Whether you need a custom profile for a unique design or standard shapes for a simple framework, aluminum extrusions can be tailored to suit your requirements.

The extrusion process also allows for very complex shapes, which might be difficult or expensive to achieve using other materials. This flexibility makes aluminum extrusions ideal for industries like architecture, furniture manufacturing, and electronics.

3. Cost-Effective Solution

Aluminum extrusions offer a cost-effective solution for many projects. The production process is relatively efficient, which helps to keep costs lower compared to other materials. While the initial cost of aluminum may seem higher than some alternatives, the long-term benefits often outweigh the upfront expense.

Aluminum extrusions are easy to maintain and do not require costly repairs or replacements. Additionally, aluminum is highly recyclable, which helps to reduce waste and can lower material costs over time, making it a great choice for sustainable projects.

4. Excellent Thermal and Electrical Conductivity

Aluminum has excellent thermal and electrical conductivity properties, which makes it an ideal material for projects that require heat dissipation or electrical transmission. For example, aluminum extrusions are often used in the construction of heat sinks for electronics, where their ability to quickly transfer heat away from sensitive components is essential.

Similarly, aluminum’s electrical conductivity makes it useful in applications like wiring and electrical systems, where efficient energy transmission is important.

5. Environmental Benefits

Aluminum is one of the most sustainable materials available today. It is fully recyclable without losing any of its properties, making it an environmentally friendly choice. By choosing aluminum extrusions, you can reduce your environmental footprint.

Not only is the material itself recyclable, but the manufacturing process is also more energy-efficient compared to other materials, further contributing to sustainability. This makes aluminum a great option for eco-conscious consumers and companies looking to minimize their impact on the environment.

Conclusion

Aluminum extrusions offer a range of benefits that make them an excellent choice for many projects. Their lightweight yet durable nature, versatility in design, cost-effectiveness, thermal and electrical conductivity, and environmental benefits make them a smart option for anyone looking to create long-lasting and efficient products.

Whether you are working on a construction project, designing electronics, or looking for a sustainable material for your next product, aluminum extrusions can provide the solution you need.